Polyethylene glycol (PEG) is a widely used polymer compound known for its excellent chemical stability, biocompatibility, and versatility across multiple industries. From pharmaceuticals and cosmetics to industrial manufacturing, PEG plays a critical functional role due to its solubility, safety profile, and adaptable physical properties. Understanding what polyethylene glycol is, how it is manufactured, and how different grades perform is essential for selecting the right material for specific applications.

Polyethylene glycol refers to a class of linear polyether compounds produced through the polymerization of ethylene oxide. It is commonly abbreviated as PEG and is identified by the CAS number 25322-68-3.

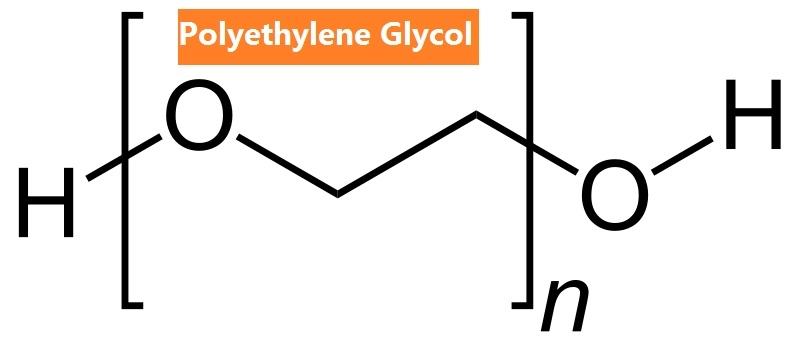

From a chemical standpoint, PEG has the general molecular formula:

H–(O–CH₂–CH₂)ₙ–OH,

where n represents the number of repeating ethylene oxide units. The value of n determines the molecular weight of the polyethylene glycol and directly influences its physical state, viscosity, melting point, and application range.

PEGs are available across a wide molecular weight spectrum, typically ranging from below 200 to several thousand. As molecular weight increases, polyethylene glycol transitions from a low-viscosity liquid to a waxy or solid material. This tunable structure is one of the key reasons PEG is widely adopted in both consumer and industrial formulations.

Polyethylene glycol is manufactured through addition polymerisation of ethylene oxide, a controlled chemical reaction process that ensures consistent molecular structure and purity.

In this process, ethylene oxide reacts with an initiator, usually water or ethylene glycol, under controlled temperature and pressure conditions. The reaction proceeds stepwise, adding ethylene oxide units to form linear polyether chains. By regulating reaction time and ethylene oxide dosage, manufacturers can precisely control the molecular weight of the final PEG product.

Modern PEG production emphasizes:

1. Tight control of molecular weight distribution

2. High product purity

3. Minimal residual monomers

4. Compliance with pharmaceutical and industrial quality standards

These manufacturing controls are especially important for PEG grades intended for pharmaceutical, cosmetic, and food-related applications, where consistency and safety are non-negotiable requirements.

Polyethylene glycol exhibits a unique combination of physical and chemical characteristics that distinguish it from many other polymers.

Key properties include:

Excellent water solubility: PEG dissolves readily in water and other polar solvents such as ethanol.

Chemical stability: It remains stable over a wide range of temperatures and pH conditions.

Non-toxicity and non-irritation: PEG is generally regarded as safe when used appropriately.

Good lubricity and dispersibility: These properties support smooth processing and formulation stability.

Strong compatibility: PEG is compatible with numerous organic and inorganic compounds.

Due to these characteristics, polyethylene glycol is extensively used across pharmaceuticals, cosmetics, food processing, textiles, papermaking, rubber manufacturing, and coatings. Its performance remains consistent across different formulations, making it a reliable functional ingredient rather than a reactive material.

One of the most important distinctions within PEG products lies in their physical state, which is directly related to molecular weight.

Low molecular weight PEGs, typically below 200, appear as colourless, transparent liquids with excellent fluidity. These grades are commonly used where easy handling, fast dissolution, and low viscosity are required. PEG 200, PEG 300, and PEG 400 are widely applied in pharmaceuticals, cosmetics, and chemical formulations.

As molecular weight increases, PEG becomes waxy or solid, with melting points rising accordingly. Medium to high molecular weight PEGs offer better structural integrity and slower dissolution, making them suitable for controlled-release systems, solid formulations, and industrial processing.

Different molecular weights serve different technical purposes. For example, PEG 600, PEG 800, and PEG 1000 balance processability with mechanical stability, enabling use as lubricants, plasticisers, release agents, and formulation bases.

Selecting between liquid and solid polyethylene glycol depends on processing conditions, end-use requirements, and functional performance expectations.

Polyethylene glycol is widely recognized for its high safety profile when manufactured and applied according to established standards. It is non-toxic, non-corrosive, and non-irritating, which explains its extensive use in products designed for human contact.

In pharmaceutical applications, PEG is used as:

A drug carrier

A matrix material

A controlled-release agent

Its biocompatibility allows it to interact safely with biological systems without causing adverse reactions when properly formulated.

In cosmetics and personal care products, polyethylene glycol functions as a humectant, solvent, and emulsifier, contributing to moisture retention and formulation stability. Regulatory authorities in multiple regions permit PEG use in consumer products, provided it meets purity and quality specifications.

As with any chemical substance, safety depends on molecular weight selection, formulation design, and compliance with regulatory guidelines. When sourced from qualified manufacturers and applied appropriately, polyethylene glycol remains a reliable and well-established material across human-use industries.