After more than a decade working with polymer raw materials across pharmaceutical, cosmetic, and industrial supply chains, I can say with confidence that Polyethylene Glycol (PEG) is one of the most versatile and misunderstood materials newcomers encounter. Many people recognize the name but underestimate how profoundly PEG molecular weight, structure, and grade selection influence performance in real-world applications.

This guide is written for those who are new to PEG but want to understand it properly—not just what it is, but why it behaves the way it does and how professionals choose the right PEG for the job.

Polyethylene Glycol, commonly abbreviated as PEG, is a synthetic polyether compound produced by the polymerization of ethylene oxide. It is known for its excellent water solubility, chemical stability, and biocompatibility, which explains why PEG appears in such a wide range of industries.

From my experience, beginners often assume PEG is a single product. In reality, PEG represents an entire family of polymers, typically identified by a number (for example, PEG 200, PEG 400, PEG 6000). That number roughly corresponds to the average molecular weight, which is the single most important factor affecting PEG’s physical form and functionality.

At room temperature, PEG can appear as:

• A clear liquid (low molecular weight PEGs),

• A semi-solid paste, or

• A white waxy solid (high molecular weight PEGs).

This variability is exactly what makes polyethylene glycol so valuable—and so technically nuanced.

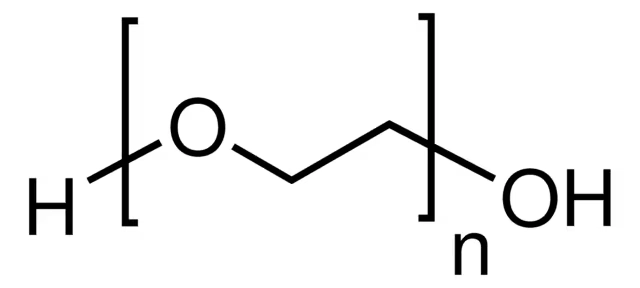

At the molecular level, PEG consists of repeating units of –(CH₂CH₂O)–, terminated by hydroxyl (–OH) groups. This seemingly simple structure gives PEG several defining properties:

• High water solubility across a wide molecular weight range

• Low toxicity and good biocompatibility, especially pharmaceutical-grade PEG

• Chemical inertness, meaning PEG rarely reacts with active ingredients

• Excellent lubricity and humectancy

• Predictable viscosity behavior

In practical formulation work, I have found PEG particularly forgiving. It blends easily, improves texture, and enhances stability without introducing unexpected side effects—assuming the correct molecular weight is chosen.

Another often overlooked advantage is PEG’s thermal stability. Compared to many organic solvents or plasticizers, PEG maintains performance over a broader temperature range, making it suitable for both processing and end-use environments.

If there is one lesson I emphasize to new formulators, it is this:

Molecular weight defines PEG behavior.

• Typically liquid

• Used as solvents, plasticizers, and carriers

• Common in pharmaceutical syrups, injectables, and cosmetic serums

• Semi-solid to soft solid

• Function as ointment bases, emulsifiers, and binders

• Frequently used in topical drug formulations

• Solid flakes or powders

• Provide structural support, film formation, and controlled release

• Widely applied in tablets, industrial processing aids, and polymer modification

From a manufacturing standpoint, PEG grades also differ in purity, residual ethylene oxide content, and regulatory compliance. Pharmaceutical-grade PEG and industrial-grade PEG are not interchangeable, a distinction that becomes critical in regulated markets.

Over the years, I have seen polyethylene glycol quietly support countless products without drawing attention to itself—precisely because it works so reliably.

PEG is widely used in:

• Drug delivery systems

• Tablet binders and coatings

• Laxatives and osmotic agents

PEGylation, where PEG chains improve drug stability and circulation time

Its biocompatibility and predictable metabolism make PEG a cornerstone of modern pharmaceutical formulation.

In personal care products, PEG functions as:

• A humectant

• A solubilizer

• A texture modifier

PEG helps creams spread smoothly, shampoos rinse cleanly, and active ingredients distribute evenly—benefits consumers feel even if they do not recognize the ingredient name.

Industrial-grade PEG plays an essential role as:

• A lubricant and anti-static agent

• A dispersant in pigments and inks

• A processing aid in rubber, plastics, and ceramics

In my experience, PEG’s stability and cost-performance ratio make it particularly attractive for large-scale industrial formulations.

One of the most common questions beginners ask is: Is Polyethylene Glycol safe?

The short answer: Yes, when properly specified and used.

PEG is generally recognized as safe (GRAS) in many regions and is approved by major regulatory bodies for use in pharmaceuticals, cosmetics, and food-contact applications. However, safety depends on:

• Purity level

• Residual impurities

• Intended use and dosage

From an environmental perspective, PEG is water-soluble and low in bioaccumulation risk, though biodegradability varies with molecular weight. Responsible manufacturers increasingly focus on controlled production processes and waste management to minimize environmental impact.

Selecting the correct polyethylene glycol is less about brand names and more about technical alignment.

Based on years of formulation and sourcing experience, I recommend evaluating:

1. Target molecular weight range

2. Required purity and regulatory compliance

3. Physical form needed for processing

4. Compatibility with other formulation components

5. Supplier consistency and documentation

For beginners, the biggest mistake is choosing PEG based solely on cost. In reality, a well-matched PEG improves performance, reduces reformulation cycles, and lowers long-term production risk—a principle especially important for publicly listed companies operating at scale.

Polyethylene Glycol is far more than a common auxiliary material. It is a strategic component whose molecular design, grade selection, and application knowledge directly influence product quality and reliability. For newcomers, understanding PEG thoroughly is an investment that pays dividends across formulation, manufacturing, and compliance.

With the right technical foundation, PEG becomes not just easy to use—but powerful.